One of the surprises concerning wood racks is that they can be as private to personal preferences as the collectibles they show. A good woodworker can create via milling as well as forming some very impressive pieces. Time to concentrate on some of the benefits of timber wall surface shelves and also the value they give your house.

No matter which place the shelving is install in the result will certainly be a very pleasant addition to the room. The elegance as well as longevity of attractive racks constructed from glass and also glass application by those curious about effective garage arranging make them a very first selection by property owners and also apartment residents that prefer a stylish however durable option to a shelving trouble. Whether selecting a 3 tier or 4 rate stand-alone glass shower racks, frozen glass edge racks that need to be bolted to the bathroom wall surface with steel braces for stability or toughened up glass panels qualified of standing up to two hundred and also fifty pounds for the garage, the fulfillment appreciated from the attractiveness and simplicity of upkeep can be enjoyed for a long time. Glass shelves are a genuine decorative as well as practical commercial boon that reflects a growth of preference and understanding.

The wall surface shelving device is an extremely powerful principle because it can be utilized for a lot of various things. You can store your books on it sure, yet you can also utilize it to hold up your trophies for all to see, you can utilize it to store things like power tools to put them right at your finger suggestions in the garage. You can also use them to display nearly anything such as dolls, sculptures, as well as clocks.

The cost of your rack will be greatly based on the product, as well as additionally the cost of the braces. Constantly inspect out various house renovation stores to compare rates. Another option would certainly be to go to on the internet seller web sites as well as check out for the very best cost.

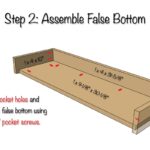

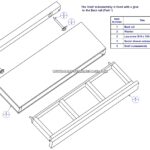

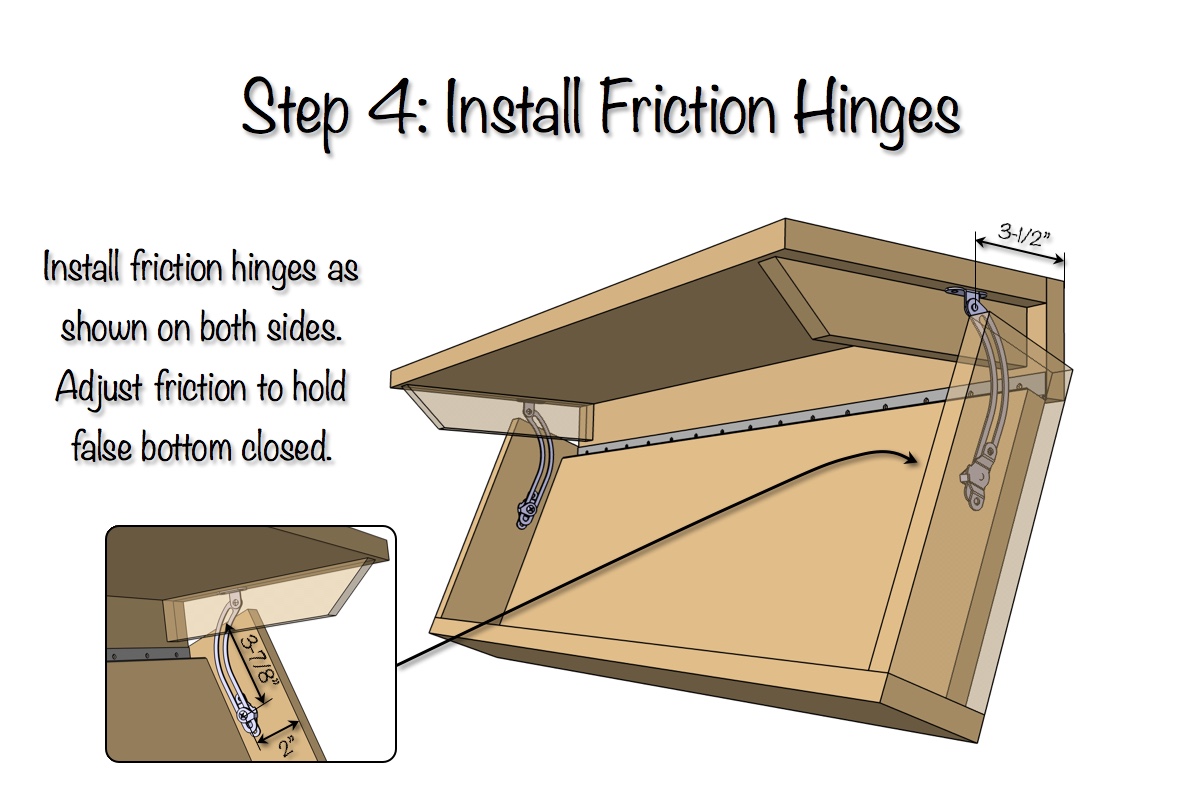

Picture Gallery of Diy Secret Floating Shelf Free Plans Rogue Engineer Step With Compartment Command Hooks Weight Capacity Shelves Oak Screws For Hanging Garage Organization Kit Entryway Coat Rack